SAF demand and supply

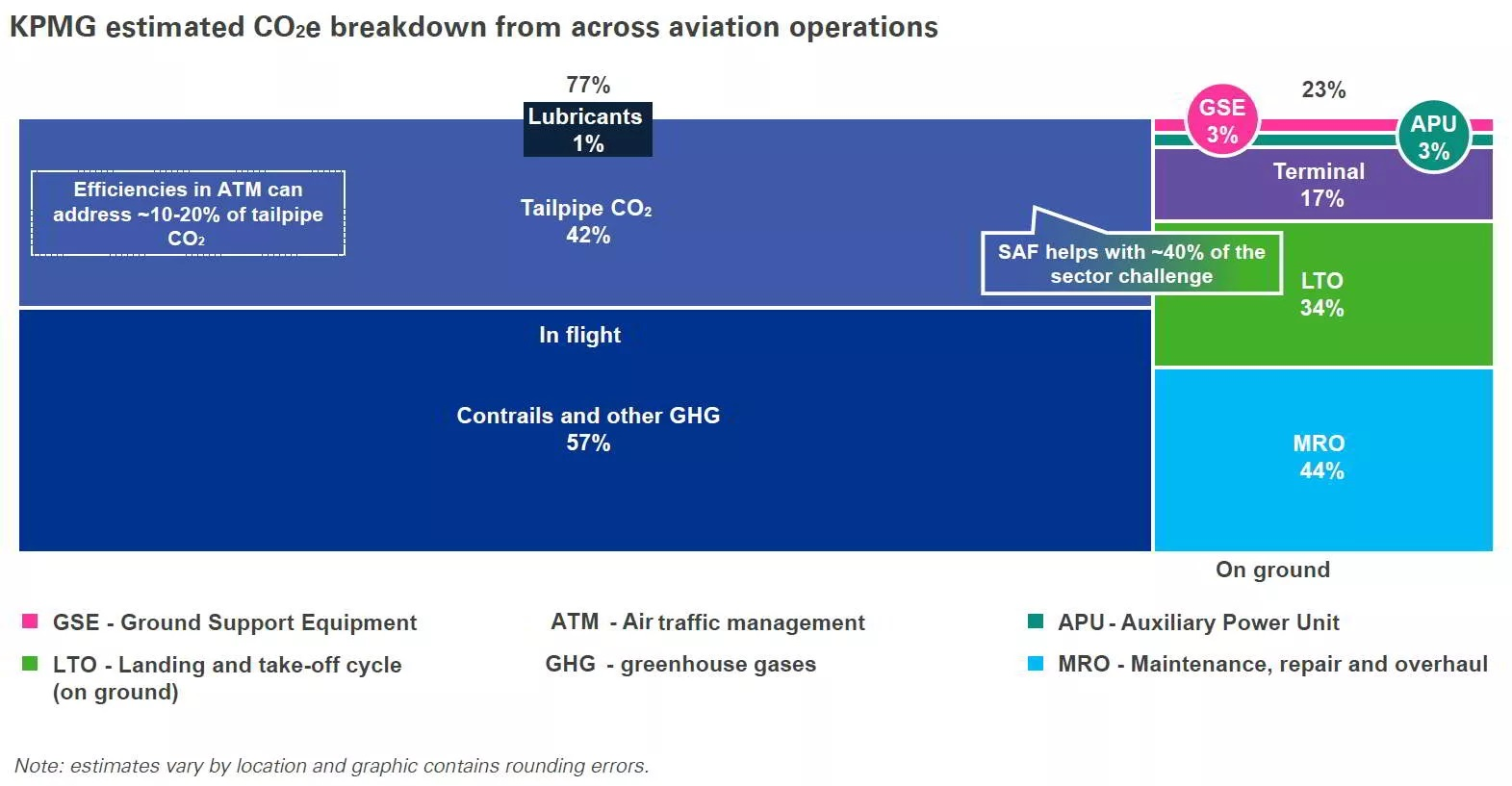

Like most of the low carbon road fuels blended with petrol today, SAF can be used in existing planes and engines. While SAF is very similar to conventional kerosene, it delivers substantially lower greenhouse gas emissions (GHG) than Jet A-1– typically around 80%.

These emissions are saved throughout the production process, as feedstocks used to make SAF have lower lifecycle carbon emissions than fossil jet.

Given that significant CO2 savings can be achieved with existing fleets, voluntary demand for SAF by airlines is growing rapidly, driven by corporate carbon reduction targets, mounting policy attention, and some passenger interest. Many airlines are already seeking to secure supplies over multi-year periods. This demand will firm up during the 2020s as national SAF mandates come into effect – especially from 2025 onwards – with a focus in Europe and an evolving picture in the rest of the world. Mandates are likely to start low but tighten rapidly during the 2030s and beyond. EU regulators are leading the charge: jet fuel supplied to EU airports will need to be 2% SAF by 2025, increasing at 5-year intervals to reach 63% in 2050, of which 28% would consist of e-fuel. Sweden, Norway, and France all have their own SAF mandates in place and the UK has announced plans for a mandate to be introduced in 2025, reaching 10% SAF by 2030.

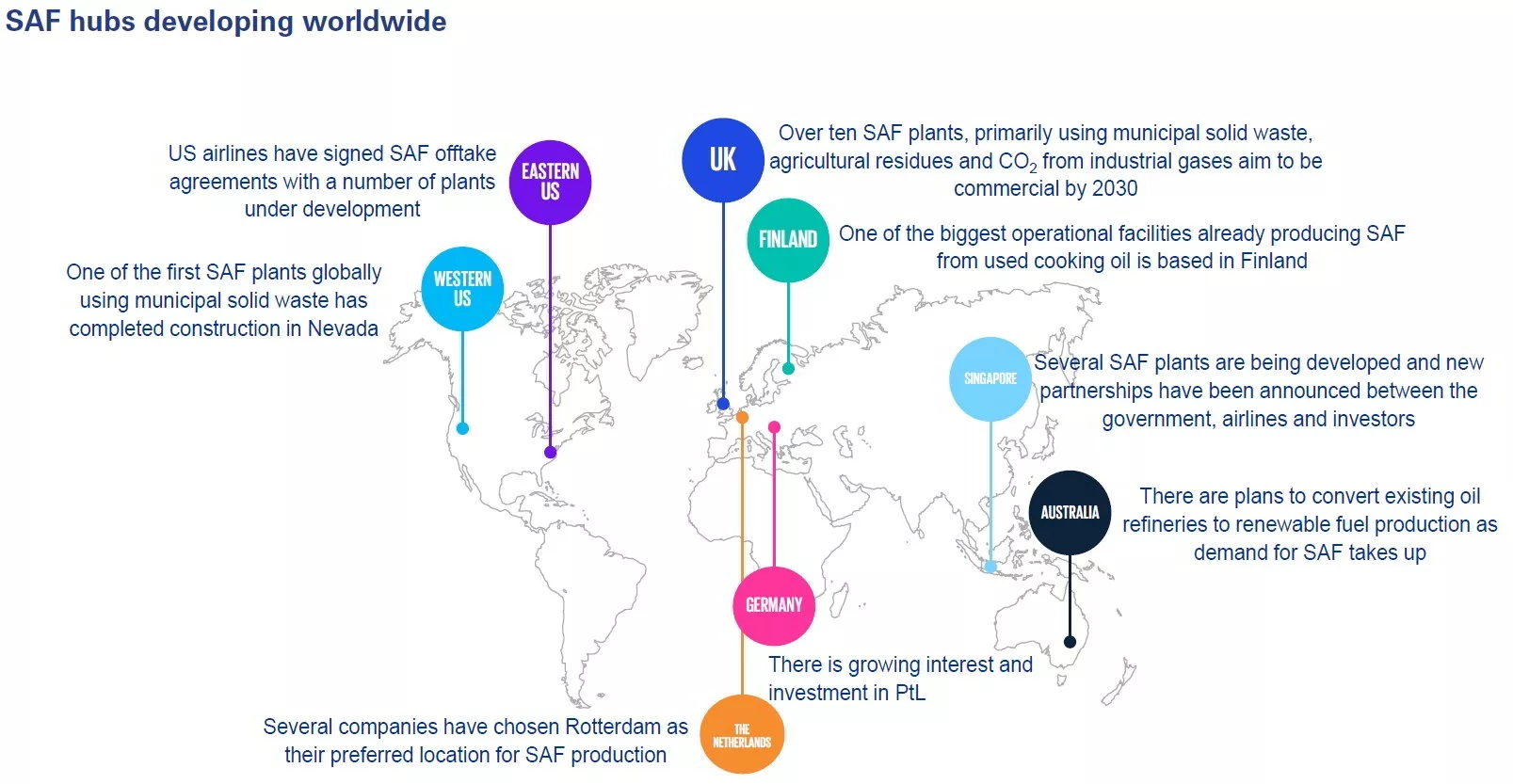

Meanwhile, the US has set a SAF production target instead, of at least 3 billion gallons per year by 2030, supported by a mix of tax credits (a maximum of $1.75 per gallon for SAF) and new funding for SAF R&D. California, whose Low Carbon Fuel Standard sets the global standard for SAF incentivization, has recently passed legislation mandating that SAF should comprise 20 percent of aviation fuel consumed in the state by 2030.

Where demand mandates do not yet exist, industry is taking some voluntary initiative, with a number of partnerships announced between major airlines and fuel suppliers to trial or regularly use SAF. There are already industry-led initiatives committing dozens of operators to net zero targets, with some (e.g. the WEF’s Clean Skies for Tomorrow coalition) translating those into explicit SAF blending mandates (e.g. 10% by 2030). Governments are also aware that domestic SAF production offers fuel security as an additional benefit – a point rising quickly up the policymaking agenda.

To meet this increasing demand, SAF production facilities are being constructed, announced or developed around the world. At present, the dominant SAF feedstock is vegetable oil, either virgin or waste oil from cooking. This is converted into synthesized paraffinic kerosene from hydroprocessed esters and fatty acids (HEFA). GHG savings are achieved when the feedstock is grown, as it captures CO2 during the process. HEFA is the simplest and cheapest form of SAF, and the technology is already commercial today, but its availability will be limited by overall feedstock supply as well as by the ongoing use of oil feedstocks in road and maritime fuel – where fuels are less complex to produce and therefore offer easier profit potential than refining to SAF specifications. Feedstock prices – hard hit by the Ukraine war – currently represent the majority of the final SAF price. Their volatility can therefore create feedstock supply problems for producers.