The manufacturing industry currently finds itself in a particularly complex field of tension. Ongoing geopolitical crises, record high inflation figures in the euro area and a weak economic outlook are omnipresent threats that are straining the German manufacturing industry.

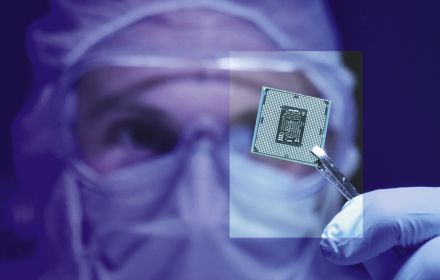

In addition, both corporate groups and SMEs continue to be affected by ongoing supply bottlenecks, despite slight easing. The increasing volatility of the economic and geopolitical framework conditions is having an impact on the industry, as is the change in the sales and procurement markets. Progressive digitalisation and the vision of Industry 4.0 are not only changing sales and production processes, but also entire business models along the individual stages of the value chain.

In addition, the requirements with regard to ESG-relevant topics (Environmental - Social - Governance) continue to increase and must be documented even more comprehensively in the future. The Supply Chain Sourcing Obligations Act (LkSG) and comprehensive reporting obligations, for example the Corporate Sustainability Reporting Directive (CSRD) and the Carbon Border Adjustment Mechanism (CBAM), can be cited as particular drivers for this development.

These are all challenges facing decision-makers in the manufacturing industry.

KPMG at the Hanover Fair

KPMG knows the relevant topics and current issues of the manufacturing industry. Our experts are positioning themselves at the Hannover Messe with industry knowledge and technology expertise and look forward to welcoming you to the KPMG stand in Hall 17.

The world's leading trade fair for industry is regarded as one of the most important international platforms for all technologies relating to industrial transformation.

Ulrich Ackermann

Member of the Managing Board, Divisional Director Tax

KPMG AG Wirtschaftsprüfungsgesellschaft

Sascha Glemser

Partner, Performance & Strategy, Head of Enterprise Performance

KPMG AG Wirtschaftsprüfungsgesellschaft

Topics in focus

With the help of digitalisation, transparency (...) is increased, risks for business models are minimised and compliance is optimised, while at the same time new procurement, production and revenue models are established. Digitalisation also helps to reduce costs and make processes faster and less error-prone. With digital tools, companies can interact more easily with their customers and reach new target groups.

Publications

Security of supply and resilience of supply chains are currently at the top of the priority list of decision makers. Manufacturing companies want and need to be more agile in the future in order to react faster to changes and make the right decisions.

Publications

New legal regulations and increasing sustainability requirements are presenting companies with new challenges. Strategic adjustments are becoming necessary for the production and value creation network due to trade policy issues and transparency pressure.

Publications

In almost all sectors, professions and regions, there are serious bottlenecks in filling skilled worker positions. Demographic change and digitalisation are increasing the pressure on the labour market and changing the requirement and qualification profiles. All of this leads companies to adapt their HR strategy to the changing framework conditions.