New safety, sanitation and hygiene procedures are all part of the “new normal” for manufacturers as plants begin to reopen after shutting down due to COVID-19. These necessary changes bring forth added expenses, coupled with lower anticipated volumes which can result in tight liquidity even if sales demand strengthens. Manufacturers need to not only focus on operational improvement but also look at their balance sheet to find ways improve their cash flow despite the challenging operating environment.

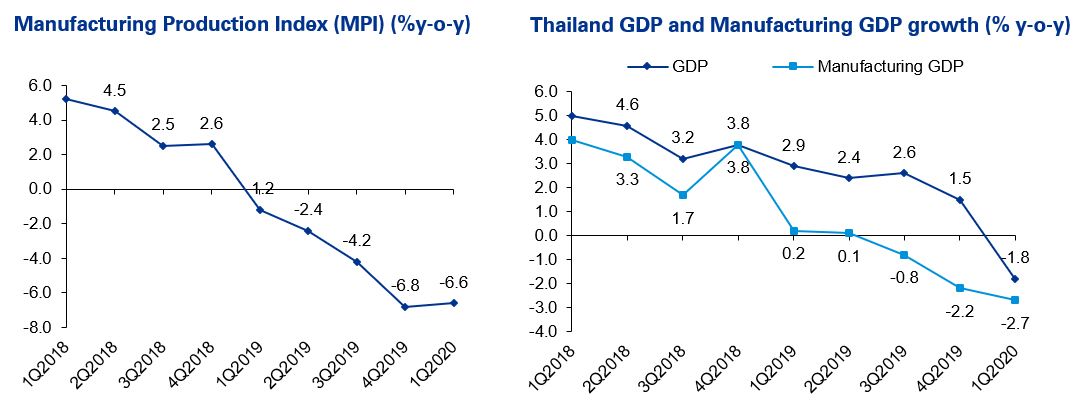

Thailand’s Industrial sector has slowed down since 2019 as a result of reduced domestic export and global demand. During the crisis in the first quarter of 2020, the Manufacturing Production Index (MPI) contracted by 6.6 percent, the majority from a consequence of the COVID-19 contraction in domestic and external demand, manufacturing production and private investment.

Thailand’s GDP contracted by 1.8 percent in Q1 of 2020, mainly due to the impact of COVID-19. According to the Office of the National Economic and Social Development Board (NESDB), it is expected that Thailand’s GDP would contract by 5.0 to 6.0 percent this year.

Manufacturers are going to operate differently and employees will need to learn new processes in order to adapt to the new normal. A flawless startup is necessary and a sustained focus is critical for keeping the plant open and averting a shutdown. OSHA has offered clear guidelines on preparing a workplace for COVID-19 which can offer the operational procedures companies should implement

to reduce the risk of exposure to employees including workplace controls to implement and guidance on developing an infectious disease preparedness and response plan.

Understanding the increased cost structure, and the impact on future production and liquidity needs to be supported with real time insights and KPIs.

Connect with us

- Find office locations kpmg.findOfficeLocations

- kpmg.emailUs

- Social media @ KPMG kpmg.socialMedia