These are pivotal times for industrial manufacturing. Manufacturers must navigate an unfamiliar environment shaped by advances in disruptive technology, economic turmoil, shifting customer expectations, uncertain labor and materials supply markets, and the world’s emergence from the COVID-19 pandemic.

Future-focused manufacturers can win by embracing digitally enabled service as the foundation of both their business and operating models.

Everywhere you look, there are signals of change for aftermarket and field service in industrial manufacturing.

Growth, efficiency and ESG are top of mind of many executives in the manufacturing sector at the moment. We at KPMG expect that the share of service business and especially the services driven by digitally connected products is to grow significantly – connectivity and IoT data are key levers also for both efficiency and ESG agenda along the industrial value chains.

Annika Tanttinen

KPMG Connected Enterprise and Business Transformation

Signals of change

Based on the signals of change, KPMG professionals have identified five strategic imperatives that manufacturers should focus on to accelerate and complete this shift.

Developing data, analytics, and AI capabilities are the top actions their organization will need to take over the next five to ten years to address.

Lower service costs, enhanced service, new offerings and revenue sources, enhanced customer value, and loyalty are some of the benefits that manufacturers can derive from digitally enabled aftermarket and field services.

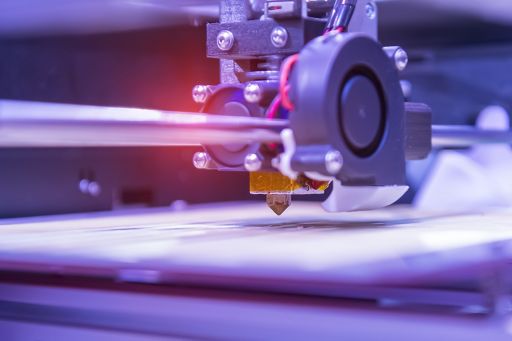

The digitization of aftermarket and field service opens the door for organizations to move beyond a traditional manufacturing business model.

Organizations are finding that they need to move beyond a product-focused culture or even a culture of functional excellence.

As manufacturers transition to connected products and platforms, the amount of data generated and transmitted is increasing exponentially, and the importance of data security is further elevated.

In this report, KPMG professionals explore the opportunity for industrial manufacturers to drive improved customer experience while enhancing efficiency and effectiveness through digitally enabled aftermarket and field service. We also discuss the challenges manufacturers are experiencing with their current efforts and the capabilities that are needed for success

KPMG Connected Enterprise

KPMG professionals can help you harness technology to build a connected enterprise. That's an enterprise where your front, middle and back offices are aligned. An enterprise where you're more connected with your customers, employees and business partners. An enterprise that enables you to respond quickly to market signals and pivot to help seize opportunities as they arise.

KPMG Connected Enterprise is a digital transformation approach, that’s industry-specific and customer-centric. It helps focus critical processes, functions, and relationships of a business on meeting customer expectations, creating business value and driving sustainable growth in a digital world.

Organizations that invest purposefully in these capabilities are twice as likely to meet customer expectations, achieve their objectives and deliver return on investment.

You can discover how connected your organization is by using our diagnostic tool. It assesses you against industry best practice and highlights the opportunities and challenges that may affect your ability to become a connected enterprise.

- 2xImpact

Learn more about KPMG firms' industrial manufacturing practice or contact a KPMG professional who is ready to help you address new challenges and drive growth.

Related insights

Get in touch

Annika Tanttinen

KPMG Connected Enterprise and Business Transformation

KPMG Suomi

Anders Hahnsson

Director, Head of Industrial Manufacturing

KPMG Suomi