Technology in action: How the industry is embracing innovation

Technology in action

Is the vast increase in data improving transparency or clouding the issue?

Is the vast increase in data improving transparency or clouding the issue?

One of the common sentiments amongst survey participants is the additional complexity created by systems and technology. The manual, disconnected cost, risk and scheduling systems of the last generation may have lacked a certain sophistication, but many believe they managed to deliver practical, workable (if limited) functionality and reports.

Another respondent comments that: “We’re spending 80 percent of our time collecting data and 20 percent of our time analyzing it. With technology enhancements, we’re trying to flip those percentages.”

The project owners and engineering and construction companies in the survey certainly appear to have an impressive and broad array of different platforms for planning, monitoring and controlling their capital projects. But few say they have the resources to analyze and make sense of the data generated by these disparate systems.

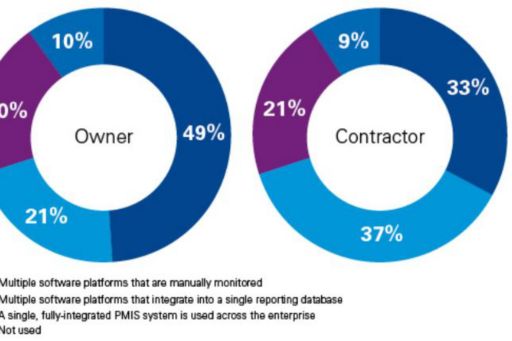

As evidence of this shortfall, just 36 percent of engineering and construction firms and 21 percent of owners say they utilize advanced data analytics in addition to cost and schedule analytics. This is not surprising, given that the majority of engineering and construction firms – as well as owners – claim to use multiple software platforms that are manually monitored. This multiple approach adds complexity to advanced data analytics, making it difficult to process information and generate insights. It is also highly cumbersome, consuming large amounts of employee time; time that could be better spent screening and monitoring data, to help detect project issues and discrepancies.

Predicting the demand for people

It’s extremely difficult to forecast resource demand for a project – ensuring the right number of people, with the right skills, are in the right places at all times. This is especially tough for larger, longer projects involving hundreds or even thousands of workers, or when certain phases of the project are accelerated. The widening talent gap within the industry only adds to the challenge. In this complex environment, ballpark estimates just won’t do.

One of the most important weapons in a construction owner’s arsenal is the ability to forecast these needs accurately. It ensures that you don’t have shortfalls holding up progress, or idle workers pushing up costs. And with a battle for scarce skills, it should help secure the right people ahead of competitors.

Technology opens up powerful project tracking tools that collect valuable project data on staffing and workload. When integrated into their planning processes, this can help organizations better manage and forecast people resources to align with project and organizational goals.

Many of the respondents to this year’s survey appear to fall short of this goal. Just 36 percent of engineering and construction companies – and only 21 percent of owners – claim to use advanced data analytics for project-related estimation and performance monitoring.

Integrated, real-time project reporting: Myth or reality?

Has the promise of integrated systems really delivered? Although the cutting edge visionary companies in the survey claim to enjoy fully integrated, centralized project and portfolio reporting, the majority of respondents state that their organizations continue to use manual processes and multiple systems.

It seems that the dream of ‘one button’ to get all project information is yet to be realized.

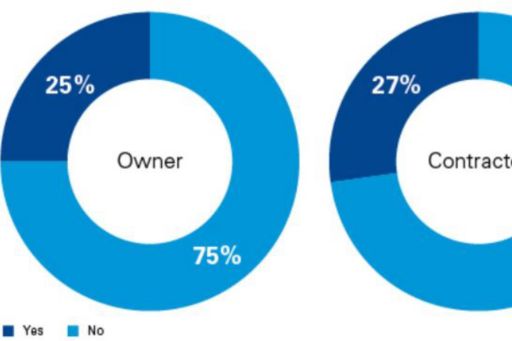

Can you ‘push one button’ to obtain fully integrated, real-time project data?

Respondents’ technology driven project management information system (PMIS)

When used effectively, a project management information system (PMIS) lets engineers and project managers communicate project status swiftly and accurately. It can dramatically improve project planning, scheduling, monitoring, and controlling.

PMISs help both owners and contractors gather reliable information for claims against performance and cost, and to reduce or prevent contract compliance disputes. The powerful analytics of PMIS tools give owners and contractors greater insight into the cost, schedule, quality, and safety performance of projects. Contractors and owners alike can accurately forecast the amount of resources required when the project scope changes, ensuring that materials and labor are budgeted and scheduled efficiently.

Forty-one percent of respondents say their companies have multiple software platforms that are manually monitored. And only 20 percent have a single, fully integrated PMIS across the enterprise. Without fully integrated automation, the effectiveness of these tools is severely compromised.

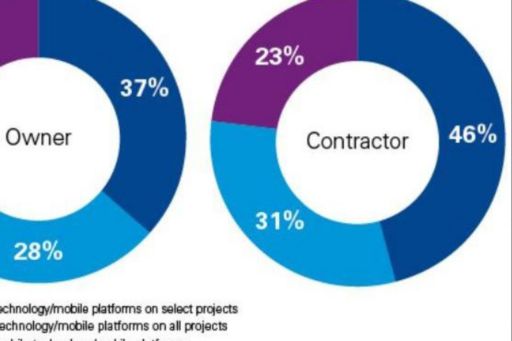

Use of mobile technology on engineering and construction projects

To view the full survey findings, download the complete report.