With Earth Overshoot Day approaching, James Dalton looks at the R&D required for Ireland to introduce a circular economy.

Earth Overshoot Day is the day every year when humanity’s consumption of resources outstrips Earth’s ability to regenerate this usage. This year it falls on 2 August, clearly demonstrating that as a planet we are living beyond our means. We are consuming the resources of 1.75 Earths per year and this rate is accelerating. When the UN first began monitoring this in the 1970s, Earth Overshoot Day was 30 December. In 50 years we have lost almost half a year to consumption.

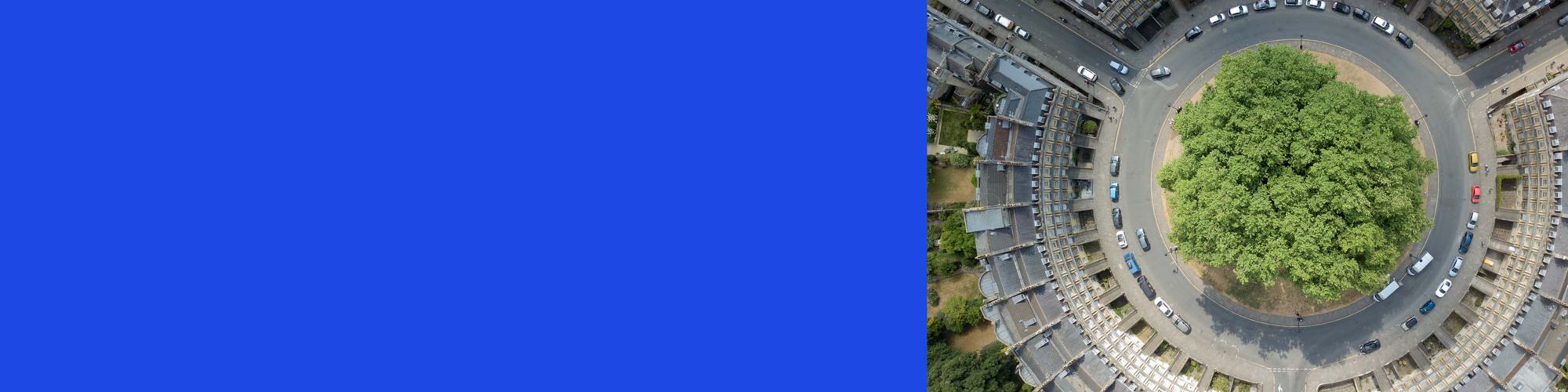

Overuse is designed into our economy; we extract, process, and then dispose of these materials wasting any further potential. This linear usage has resulted in the rapid consumption of Earth’s resources that has brought us here. A circular model of resource usage has been proposed to help combat this.

Circular economy

The circular economy proposes viewing waste as a design flaw. Rather than materials being extracted, processed, used and disposed of, they are recovered and reused sustainably from existing products, minimising the extraction of new materials.

Materials can be finite technical materials, e.g. metals, plastics, etc., or biological renewable ones e.g. wood, crops, etc., both requiring distinct pathways to manage sustainable usage. Products and processes are designed with longevity, reusability and recyclability in mind to reduce and eliminate waste. Used technical materials are reprocessed back into raw materials to be reused, and biological materials are recycled where possible then returned to natural cycles regeneratively.

The circular economy’s goal is underpinned by three principles:

- Eliminate waste and pollution

- Circulate products and materials

- Regenerate nature

Not every industry can meet all three, however action needs to be taken where possible. Sustainable products need to achieve the same or better performance, utilising less energy and materials. This requires a paradigm shift in innovation. Existing technology and improved practices and behaviours will contribute to achieving a circular economy, however technological advances in fields such as renewable energy, material science and process engineering are essential to the widescale implementation of circularity and sustainability.

Circularity loops and sustainability

Circularity and sustainability are related but distinct concepts. Circular models contribute to sustainability, however not all sustainability initiatives are circular. Sustainability is a broad concept that aims to meet current needs without impacting on future needs, whereas circularity focuses on the specifics of material cycles as a method of achieving sustainability. In its ideal form circularity is a closed loop producing no waste, compared to a linear model where natural resources are collected and processed into products that are then turned into waste. However, not all loops can be fully closed and there are gradations in efficiency in between these two points.

The ultimate goal is to create a self-sustaining closed loop where resources are used to make products that are reused, shared, repaired, refurbished, remanufactured and recycled resulting in a no-waste system. This reduces resource wastage and lessens pollution and carbon emissions.

There are three main approaches to creating loops:

- Narrow the loop, building greater efficiency and reducing waste

- Slow the loop, extending product lifespan and reducing associated waste

- Close the loop, reintegrating waste into the supply chain through recycling and capture of materials

The ecological and societal advantages of this model are tremendous, leading to environmental and biodiversity regeneration. There are also numerous business advantages. Reuse of materials can reduce costs and material value is maximised through extended use. It also brings stability of supply, particularly with rarer elements, and improved consumer sentiment.

Research, development and innovation

Many of the challenges a circular economy brings are societal and organisational, requiring changes in consumer attitude and improved logistics. Whilst there is a strong desire for change among consumers, there’s also the expectation of performance and continuous improvement. For large scale adoption, circular solutions need to deliver comparable quality, and performance in addition to sustainability.

As such, a shift is required at all levels of product design and manufacture requiring significant new knowledge. Most products are designed with functionality and cost as the main drivers. A shift to a circular economy puts significantly more weighting on longevity, ease of repair, and material recovery to improve overall sustainability. This requires the development of new processes for product manufacture, repair, refurbishment, remanufacture and ultimately material recovery. These changes will also impact on cost, potentially requiring new economic models.

Product lifespan & maintenance

Longevity is essential in a circular economy. A finished product represents significant energy investment, with the intact functional product more valuable than the sum of its parts or its recyclable materials. Increased product lifespan is required, especially those viewed currently as single or limited use. This requires all aspects of consumer goods to be redesigned for improved longevity with comparable performance.

Wastage can also be improved by making products easier to repair, refurbish, and remanufacture. Achieving this at a local level would significantly improve sustainability and allow greater customer empowerment. There is already a significant right to repair movement globally and redesigning products with home repair in mind would impact on product longevity. Should this not be wholly possible through design change then more efficient centralised processes will need to be developed.

Products will potentially require redevelopment to utilise more sustainable materials, to incorporate recovered materials, or a combination of both. A desire for shorter logistics may also impact on the materials available. These changes will require research to ensure that performance and sustainability targets are met. This requires the development of new materials but also of efficient material recovery and decontamination/ reconditioning processes from products that have reached end of life.

Funding R&D

R&D is essential to the success of a circular economy and improved sustainability. This comes with significant costs, but these are modest compared to the cost of inaction. As consumer sentiment shifts towards increased sustainability, those that innovate and bear these costs will be at a significant advantage versus those that don’t.

There are a number of funding mechanisms to help offset costs associated with this development. In Ireland, the R&D tax credit allows companies to recoup 25% of their qualifying R&D spend (subject to the usual terms and conditions). This is a substantial support for companies seeking to develop and refine new technologies. There are also grants available to support R&D in general and sustainability specifically, e.g. the Climate Planning Fund for Business administered by Enterprise Ireland and the EXEED grant scheme administered through the SEAI. While these supports are welcome, an improved scheme with greater financial support for ‘Green R&D’ would help speed up the sustainability transition.

Going forward

Fundamental societal change is required to meet the challenges of carbon reduction and sustainability. Development of new technologies will be a key enabler of this change. Ultimately, we need to view all materials as borrowed from nature, and like all good borrowers return what we have borrowed in good order. This necessitates a root and branch change in how products and processes are developed, used and recycled.

This R&D is essential if we are to turn back the clock and confine Earth overshoot day to the history books.

Get in touch

Harness the full potential of your research initiatives with our tailored strategies and in-depth industry knowledge. We'll help you unlock funding opportunities, and accelerate your journey to success.

Contact James Dalton of our R&D incentives team for more.

James Dalton

Director

KPMG in Ireland