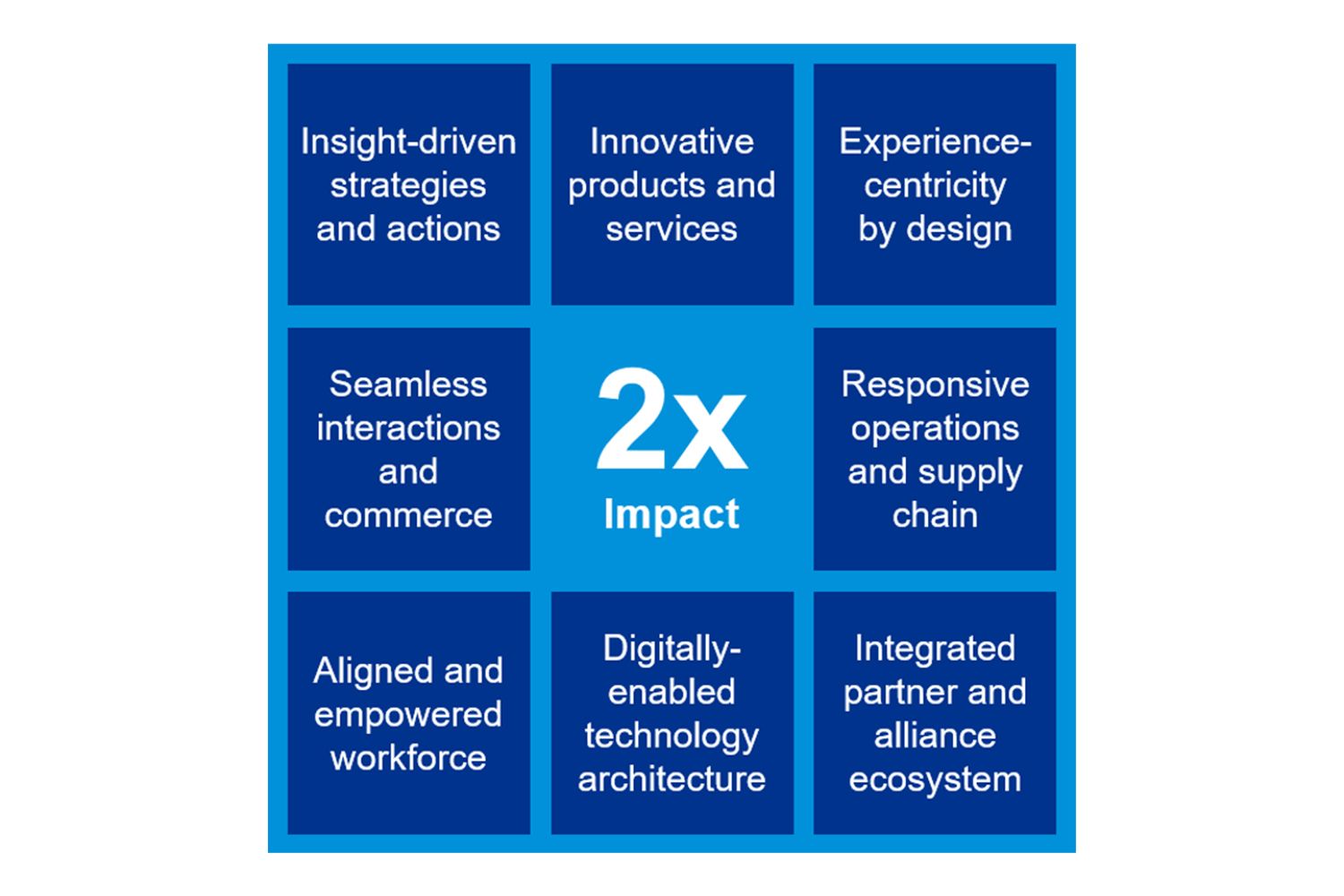

Successful digital transformation is sum of many things. It can be difficult to know where to start and where to focus organizations transformative efforts. To help with this, KPMG has researched and developed Connected Enterprise method that can help organizations execute digital transformations. Connected Enterprises consists of eight main capabilities that each successful organization possess. In this article, we are focusing on how responsive operations and supply chains can serve customers better.

Customers have higher expectations than ever before. An increasingly connected and fast-paced world is raising the expectations and requirements placed on businesses. Customers want services personalized and tailored for their individual needs, and everything should be convenient and fast.

The leaders among connected enterprises know that they must install the right operational practices and supply chains, if they are to honor their promises to customers. They must lead their organizations efficiently and with the necessary agility in order to fulfil their customer promises in consistent and profitable ways. With the right enterprise decision analytics, operating models and procurement services, you can transform your organization’s processes and provide both an outstanding, seamless experience for the customer and reduced costs for your business.

“The Future of Supply Chains: the Universal Route to Success”, an article in KPMG’s “Future of” series, identifies those areas that organizations must focus on, if they wish to keep up with the pace of digital transformation and empower their supply chains.

Putting the customer first and utilizing platforms effectively

The competition is constantly getting tougher in terms of differences in customer experience. New businesses are entering the market with new business and operating models. Customers are more alert and more capable of easily comparing the quality and prices of products and services in an increasingly connected world. Supply chain management is no longer purely about reducing costs. In the future it will focus more on service differentiation and increasing market share through value-adding and premium fulfillment options.

The number and variety of digital platforms have increased in recent years, enabling organizations to connect retailers and customers. Supply chains can be bought “as-a-Service” from third-party providers. Successful companies are those that have learnt how best to utilize digital platforms to drive business growth. The key benefits of direct-to-customer (D2C) sales models are their short supply chains, greater efficiency and value creation.

Leveraging cross-functional data and exploiting micro supply chains

Automatization and digitization don’t just reduce costs and drive efficiencies; they also generate a massive amount of data. But in order to unlock the benefits of data, it must be analyzed and used efficiently. Organizations are already using advanced analytics to optimize supply chains in real-time and to forecast the future. However, the acceleration of digital transformation and the greater use of emerging technologies will require ‘control towers’ to cope with the enormous amount and variety of inputs that can overwhelm decision-making and slow down systems. Tomorrow’s organizations will likely gravitate towards cognitive decision centers (CDCs), which take a cross-functional view of supply chains and connect the front office with back-office functions.

In order to meet growing customer demand, successful organizations will separate out the operations associated with different business streams into self-contained, micro supply chains. Each supply chain can then be optimized to meet the needs of each specific customer segment.

Unlocking our imagination

It is already apparent that the world is changing in ways that cannot be stopped. Supply chains are vulnerable to pandemics and geopolitical crises that devastate environments requiring resilient supply chains. As new startups are emerging that offer more rapid trials and more innovative business models, it is important for companies to adapt to changing environments and industries. Digital transformation and changing environments unlock new possibilities. There can be no limits to our imagination when creating future and better ways to manage supply chains.