“Can we adjust the turbine blades and nacelle positions at our wind farms so that the turbines generate even more output power?” An energy company asked us to test this hypothesis; in response we created a digital twin for these power generators. One was mathematical and the other was an AI prediction model, which forecast the maximum achievable output power based on the settings of a wind turbine, as well as wind strength and direction. Through several simulations, the digital twins came up with an answer to this million-dollar question.

Our mission: to assess the current performance of the turbines and maximize their output

An energy company operating 200 wind turbines in Eastern Europe wanted to know whether it was effectively using the turbines on its wind farm, specifically:

- How efficient are the turbines at the moment?

- Can the position of the nacelle (the cover housing the turbine and where the blades are located) and angles of the blades be optimized to increase turbine efficiency under certain wind conditions and thus maximize output power?

What can the digital twin do and how is it created?

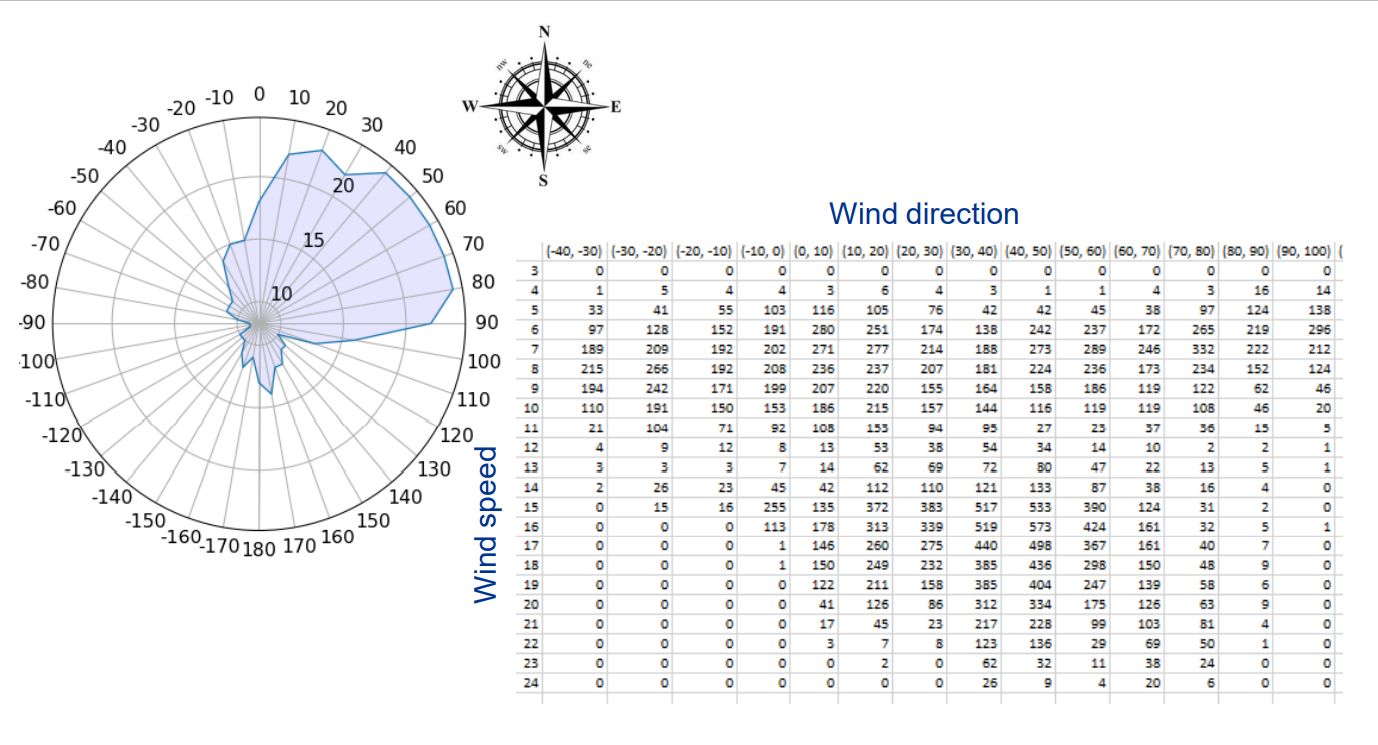

The energy company had a vast amount of measurement data available (e.g. on the performance of the turbines, depending on their configuration, airflow, and wind speed and direction) and information from external sources and the market (weather forecasts, electricity prices, etc.). In light of all this, we opted for the “digital twin” as a simulation method.

A digital twin is a fully digital model of your real-world device or system and can be an interactive, multi-dimensional physical model or even a virtual reality model equipped with Internet of Things sensors. A digital twin can also be a simulation of the performance of your infrastructure or critical parts of it. Thus, digital twins are appropriate for manufacturing, logistics or energy companies whose equipment does not enable physical testing of various scenarios.

At KPMG, we also used the digital twin concept to optimize cash-handling charges at a bank. Our simulation mapped the behaviour of a network with various branches and ATMs, as well as the demand for cash (ATM deposits/withdrawals).

We chose the DIGI TWIN simulation mainly because testing on a physical device – a wind farm (or a network with branches and ATMs) – was not possible. If it had carried out such testing, the client would have had to shut down one of its turbines, with the risk that it could be damaged if the parameters were chosen incorrectly. In addition, a simulation would take disproportionately more time.

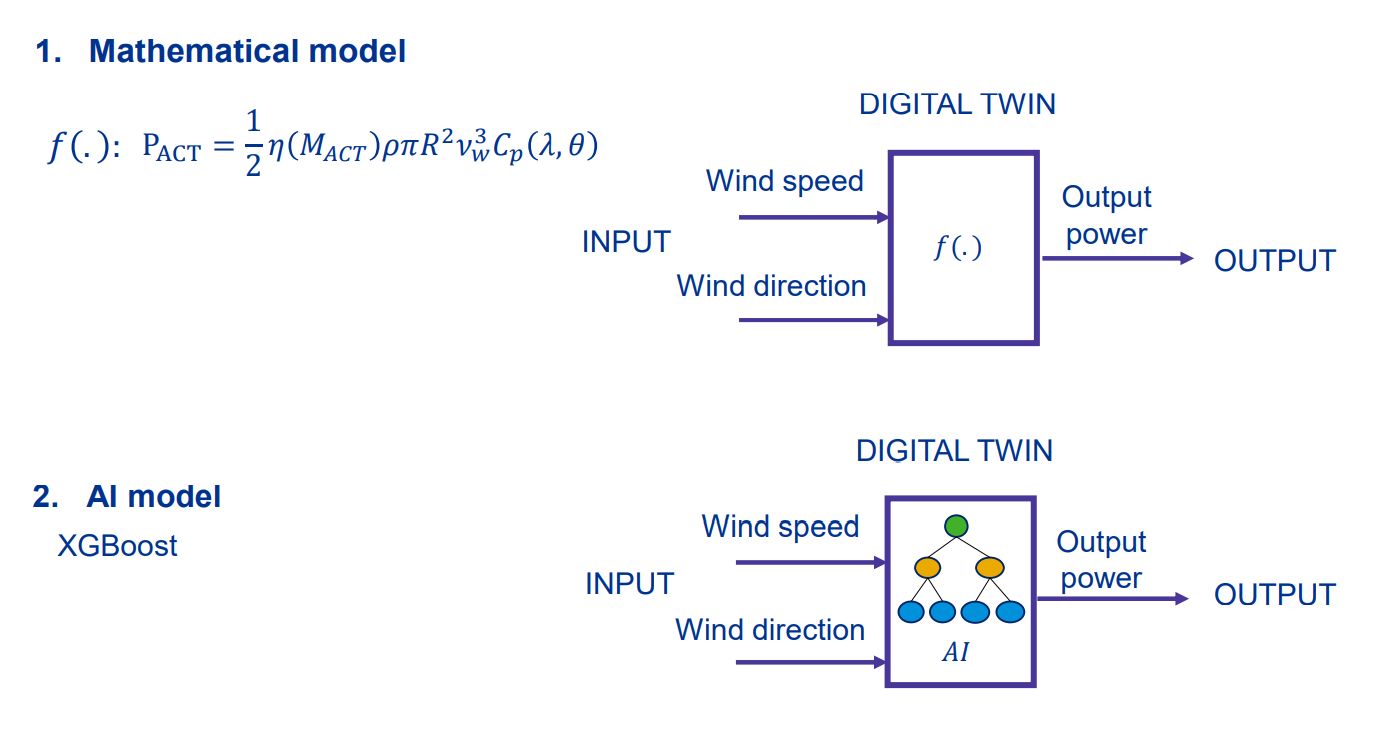

First, we devised a mathematical model (digital twin), with wind speed and direction as inputs. Using it, we verified whether the output power of the digital model coincided with the turbine output power under the same conditions.

Then, based on the mathematical model, we trained an AI model (XGBoost), thanks to which we predicted the output power in relation to different parameter configurations (nacelle position and blade angle), with suitably chosen restrictive conditions, which described the physical and technical capabilities of the turbine (for example, the maximum permissible speed of propeller rotation).

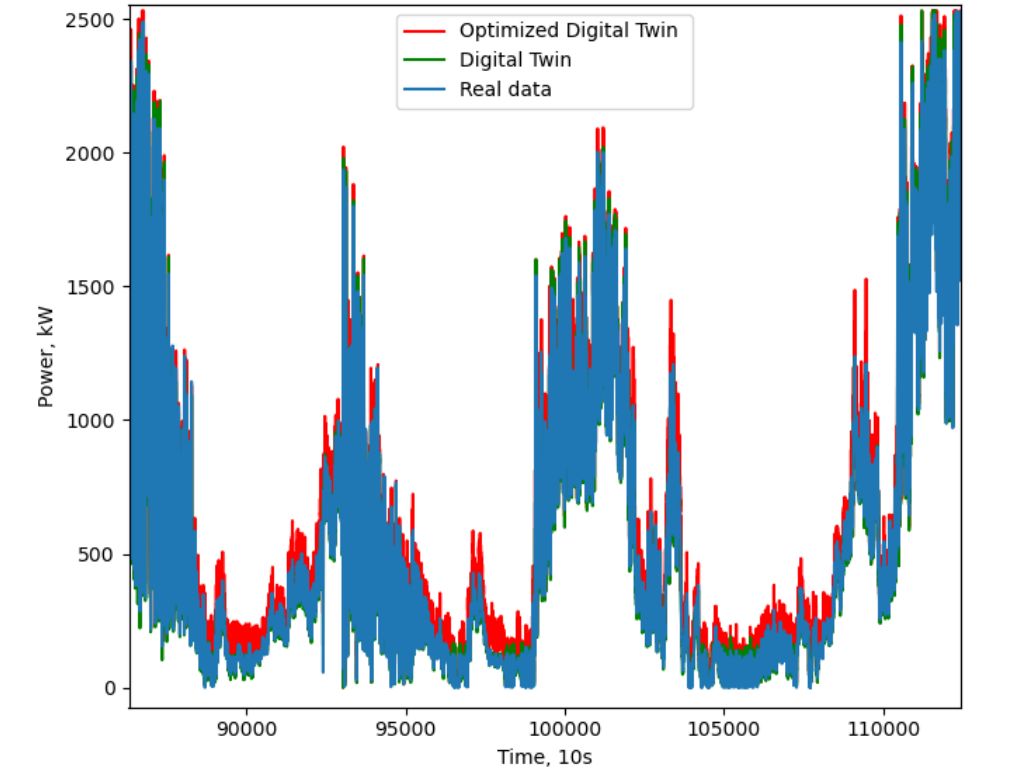

Optimization generates an extra 32 thousand megawatts

The simulation revealed that by checking the blade angle, the client could increase turbine performance by 2.73%, and with optimal settings of both the blades and the orientation of the entire nacelle, by even 2.9%. With such an increase in performance, one turbine can generate more electricity, worth up to EUR 9,300 annually. If the client carries out optimum adjustments at all its 200 wind farms, it will produce an extra 32 thousand megawatts of electricity – an additional income of up to EUR 2.2 million.

Should you be interested in this case study and would like to optimize your systems and equipment, do not hesitate to contact us.

Real data vs. digital twin